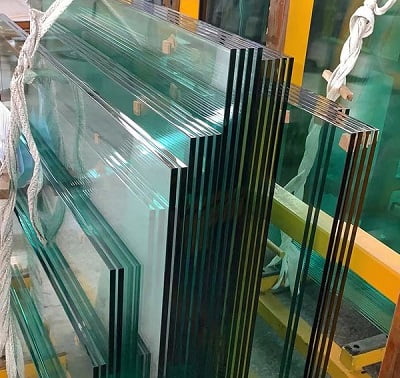

Toughened Glass

Toughened glass (also known as tempered glass) is a type of safety glass that is made to be stronger than regular glass. It is typically used in applications where regular float glass will pose a risk due to the potential of human impact.

History of Toughened Glass

Toughened glass was first developed in the early 20th century. The earliest recorded use of toughened glass was in 1909, when it was used to create windshields for automobiles. However, the process of creating toughened glass was not perfected until the 1930s.

How is toughened glass made?

Toughened glass is produced by heating float glass to its softening point and then rapidly cooling it. This process strengthens the surface of the glass and makes it more resistant to breakage and steps are as follows –

- Preparation – The glass is first cut to the required size as cutting will not be possible after the toughening process.

- Examining Glass – The glass is examined for any flaws before tempering in order to lower the possibility of breakage. Sandpaper is an example of an abrasive used to remove sharp edges. The glass is then cleaned.

- Heat Treatment – After being examined and prepared, the glass is placed in a tempering oven, where it is heated to a temperature of more than 600 degrees Celsius.

- Quenching – The glass is then quickly cooled using a high-pressure cooling technique called “quenching.” High-pressure air is used to blast the glass, which causes the outer surface to cool much more quickly than the interior. The centre tries to pull away from the outer surface as it cools. As a result, the outer surface compresses while the centre remains in tension which toughens the glass.

What are the advantages of toughened glass?

- 5x stronger than regular glass

- Heat resistant up to 250 degrees celcius

- Higher resistance to impact

- Breaks into pea-sized pebbles instead of sharp shards

What are the disadvantages of toughened glass?

- More expensive than regular glass

- Cannot be cut or drilled after tempering

- May break spontaneously if there are any flaws in the glass

What are the applications of toughened glass?

Toughened glass meets the requirements for safety glass according to AS1288 standards, this makes them ideal for a wide range of safety-related applications, such as:

- Automotive windscreens

- Building facades

- Doors

- Shopfronts

- Shower screens

- Furniture and tabletops

- Kitchen Splashbacks

- Balustrades

- Pool fences

- Tabletops

AUTHOR: Nhu Tran

Operations Manager & Glazier at Grand Glass Repairs - Door & Window Glass Replacement

Nhu Tran is a highly experienced glazier who currently works for Grand Glass Repairs in Sydney. With many years of experience in the field, Nhu has become an expert at he’s craft and can be counted on to get the job done right, no matter how challenging it may be. He takes great pride in her work and is always looking for new ways to improve her skills. When she’s not working, Nhu enjoys spending time with he’s family and friends.